Product Description

Application and Features

1. This machine is mainly suitable for automatic molding die cutting of facial film cloth industry.

2. CAD automatic nesting typesetting system can achieve the normal working efficiency of 6 traditional machines process, save more than 15%-20% of raw materials, reduce a lot of manpower and labor costs, and the shift output can reach at 800,000 pieces to 1 million pieces with high yield.

3. The technical performance index of product can meet the international advanced level.

4. The automatic waste absorption device can suck out the waste of facial mask eyes automatically, pick up the materials and then packaged directly. Meanwhile, it can fundamentally solve the damage problem of tool mold caused by mold sticking.

Related Instructions

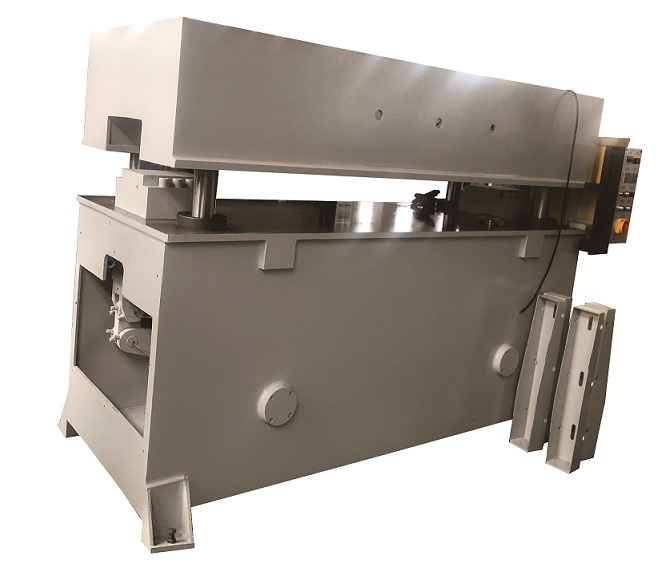

1. This equipment is the fourth generation product. The main machine is equipped with double oil cylinders, double crank connecting rod balance and four-column guiding mechanism to ensure accurate cutting depth;

2. High temperature tempering is adopted to ensure that the body never deforms and can be used for a long time.

3. The diameter of the oil cylinder is 100mm, the motor power is 3kW , the distance between the upper and lower pressure plates is 50-125mm, and the effective area of the workbench is customized.

4. PCL human-machine interface digital control system automatically sets numbers of punching times, high accuracy and positioning accuracy up to 0.2mm, saving materials, cutting speed at 30-50 times/min, high efficiency work and reducing labor intensity.

5. The feeding rack and receiving rack of the machine can be designed according to customers’ requests.

Information or Purchase

To get more information about our product or to order from our product, contact us: [email protected]