Product Description

The Principle of Ultrasonic Cleaning

Ultrasound is an oscillating sound pressure wave with a frequency greater than the upper limit of the human hearing range. Ultrasound is thus not separated from ‘normal’ (audible) sound by differences in physical properties, only by the fact that humans cannot hear it. Although this limit varies from person to person, it is approximately 20 kilohertz (20,000 hertz) in healthy, young adults. Ultrasound devices operate with frequencies from 20 kHz up to several gigahertz.

Ultrasound is used in many different fields. Industrially, ultrasound is used for cleaning and for mixing, and to accelerate chemical processes. An ultrasonic cleaner works mostly by energy released from the collapse of millions of microscopic cavitations near the dirty surface. The bubbles made by cavitation collapse forming tiny jets directed at the surface. An ultrasonic cleaner uses ultrasound (usually from 20–400 kHz) and an appropriate cleaning solvent (sometimes ordinary tap water) to clean delicate items. The ultrasound can be used with just water, but use of a solvent appropriate for the item to be cleaned along with the soiling enhances the effect. Cleaning normally lasts between three and six minutes, but can also exceed 20 minutes, depending on the object to be cleaned.

How a Sound Can Clean?

A physical effect called “cavitations” ultrasonic generates in liquid is responsible for the cleaning process. Cavitations are form when ultrasonic travels through liquid. When a sound wave travels through water, it stretches and compresses the water medium to transmit sound. When the amplitude of such sound wave increases to a level when water cannot hold the stretch, the sound literally tears the water apart, and millions of vacuumed “bubbles” are formed under such negative pressure.

The sizes of vacuumed “bubbles” increase until their equilibrium are reached; the “bubbles” then rapidly compress by water and create millions of tiny liquid jets.

The jet actions release tremendous amount of energy stored within vacuumed bubbles; each “bubble” is estimated to have a temperature of more than 5000 degree Celsius and a pressure of more than 10,000 PSI at molecular level when such implosion takes place. The huge amount of pressure releases at each “bubble” provides an ideal physical phenomenon responsible for the effective cleaning action ultrasonic cleaner offers.

Ultrasonic Cleans Cracks

Cavitation takes place everywhere liquid can reach; during the cleaning process, the article being cleaned is submerged into water or cleaning solution, millions of micro-sized “bubbles” created by ultrasonic are capable of reaching into fine trends or cracks to clean.

The specifications of the equipment

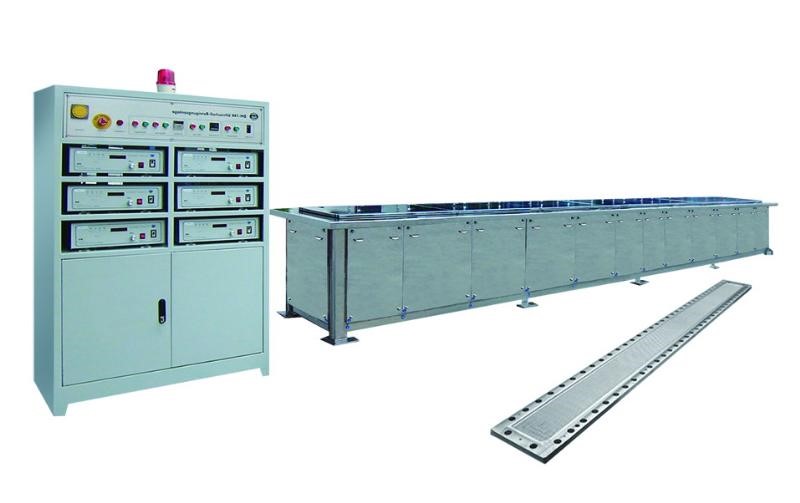

Equipment Type

DH25-14K Special ultrasonic cleaning machine for the jet strip.

Technical Indicators

1. The Working frequency: 25kHz

2. Ultrasonic Power: 0-14000W, Adjustable

3. Protection Function: with overcurrent, overload protection and Level protection and the buzzer alarm

4. Cleaning Ability: 3962X25X1mm jet strip 12pieces/time

Exact technical indicators could be varied depending on different cleaning ability.

Information or Purchase

To get more information about our product or to order from our product, contact us: [email protected]